Employee Spotlight: Philip Oglialoro

7016535987 • February 1, 2024

An Outstanding Member of the Team!

Philip Oglialoro

Life Outside of KastRock

Phil has been married to his high school sweetheart, Kelly, for fifteen years. They have been blessed with four wonderful children and family time is of the utmost importance to them. Currently, Phil and his wife have been enjoying watching their oldest daughter and son play softball and baseball. When asked about this, he remarked “The ballfields have become a way of life for me outside of work. I love watching our kids become great people through working with others for the betterment of the team.”

Teamwork Makes the Dream Work

This emphasis on teamwork

is something Phil also values in his career at KastRock. Leadership

recently added to KastRock’s warehouse inventory, to better meet the needs of their customers. When asked about this experience, Phil reflected “The work it took from the entire team to put everything together was huge. Our team works together daily and strives to make customer satisfaction the main priority.”

“Accomplishments are sweeter when they are earned through the effort of a likeminded group,” said Phil. This mindset is something that sets employees like him apart from the rest and has made him an excellent addition to the KastRock team.

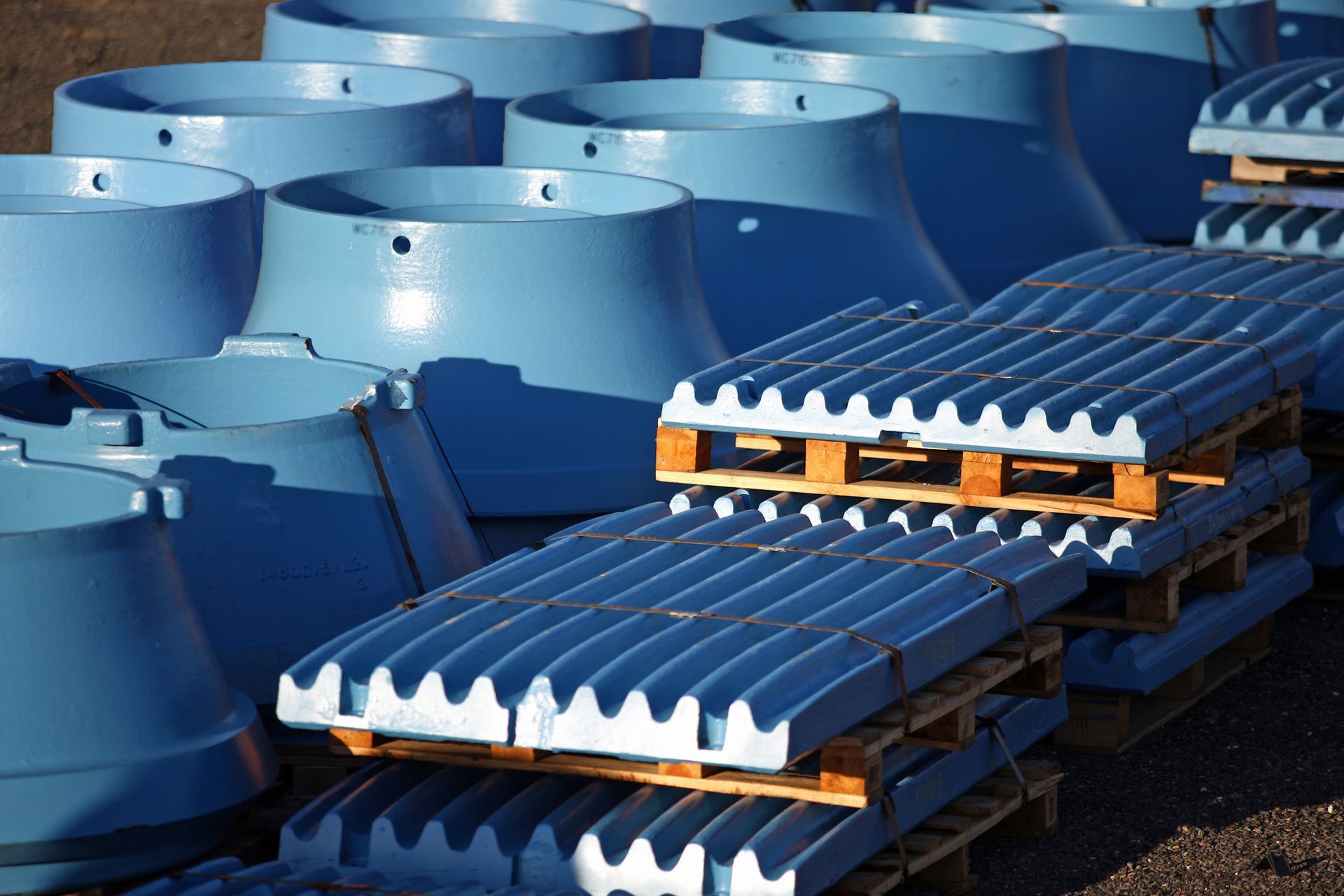

At KastRock, we’re committed to providing aggregate producers and contractors with crushing solutions that deliver higher production, consistent gradation, and dependable uptime. As a Metso distributor, we’re proud to support customers with access to some of the most trusted crushing technology in the industry. One of the most widely recognized and proven solutions in Metso’s lineup is their industry-leading range of cone crushers. Designed for efficiency, durability, and high-performance crushing, Metso cone crushers are built to meet the demands of modern quarry and mining operations. What Is a Cone Crusher? A cone crusher is a compression crusher that reduces material by squeezing it between a rotating mantle and a stationary concave bowl liner. This crushing method produces consistent aggregate sizing and a well-shaped final product, making cone crushers a go-to solution for many operations. Cone crushers are commonly used in: • Secondary crushing • Tertiary crushing • Quaternary crushing • High-volume aggregate processing • Fine material and manufactured sand applications Because of their versatility and efficiency, cone crushers remain a key piece of equipment in many crushing and screening spreads. Why Metso Cone Crushers Stand Out Metso cone crushers are trusted across the aggregate industry for their ability to deliver high production while maintaining long-term reliability. They are engineered to provide strong crushing efficiency, consistent end-product quality, and reduced operating costs. At KastRock, we understand that our customers need equipment capable of handling abrasive material, demanding tonnage requirements, and long operating hours. Metso cone crushers are built to perform under real-world jobsite conditions. Key benefits of Metso cone crushers include: • Excellent product shape and consistent gradation • High throughput and production capacity • Durable construction for demanding applications • Optimized liner wear and long wear life • Advanced automation and monitoring options Metso Cone Crusher Series Offered Through KastRock Metso cone crushers are available in multiple configurations to support different applications, production goals, and crushing stages. At KastRock, we work with customers to identify the right cone crusher series based on their material type, feed size, and desired end product. Metso Nordberg® HP Series Cone Crushers The Metso Nordberg® HP Series cone crushers are among the most trusted and widely used cone crushers in the aggregate and mining industries. Known for their high performance, consistent end-product quality, and long-term durability, the HP Series is designed to deliver reliable crushing results in demanding applications. Built to improve production efficiency while minimizing downtime, HP Series cone crushers are a strong fit for operations looking to maximize: • Throughput and overall plant capacity • Efficient secondary and tertiary crushing performance • Consistent reduction ratios and high-quality end product • Long-term wear life and dependable reliability • Crusher availability with reduced maintenance interruptions Whether you’re operating a high-tonnage quarry or optimizing an existing plant for better performance, the Metso Nordberg HP Series offers a proven solution that balances power, efficiency, and durability helping producers meet production goals with confidence. Metso Nordberg® GP Series™ Cone Crushers The Nordberg® GP Series™ cone crushers are designed for strong performance and efficient crushing across a variety of applications. GP crushers are known for their reliability and consistent output, making them a popular choice in both stationary and portable plant configurations. GP Series cone crushers are often selected for: • Secondary and tertiary crushing applications • Plants requiring flexibility and efficiency • Reliable performance with consistent gradation GP crushers provide a solid combination of capacity, productivity, and proven design. Symons™ Cone Crushers The Symons™ cone crusher is one of the most well-known and widely used cone crusher designs in the industry. Symons crushers have a long-standing reputation for durability and performance, and they continue to be a trusted solution in many aggregate operations. Symons cone crushers are valued for: • Proven, time-tested design • Strong performance in secondary and tertiary applications • Long wear life and durable construction • Compatibility with a wide range of applications For many producers, Symons remains a dependable choice for consistent crushing performance and long-term operation. Automation and Crusher Monitoring Technology Modern crushing operations rely on more than mechanical strength, they rely on optimization, monitoring, and efficiency. Metso offers automation solutions that help operators: • Monitor crusher performance in real time • Adjust closed side setting (CSS) efficiently • Improve safety through remote monitoring and adjustments • Reduce the risk of unplanned downtime • Improve overall throughput and consistency Automation gives producers the ability to operate smarter while protecting their equipment investment. Wear Parts and Support Matter Cone crusher performance depends heavily on the quality of wear parts and the support behind the machine. Metso provides OEM wear parts designed to protect the crusher while maximizing production and efficiency. Common cone crusher wear parts include: • Mantles • Bowl liners • Head and socket liners • Backing compounds • Maintenance and protective components A strong wear parts strategy can help reduce downtime, maintain consistent product quality, and lower cost per ton. Contact KastRock to Learn More About Metso Cone Crushers If you’re evaluating cone crusher options for your quarry, mine, or aggregate operation, Metso offers proven solutions built for performance and reliability. Contact us today to learn more about Metso cone crushers, available models, and how we can help you find the right machine for your application.

.In aggregate production, consistency and efficiency are the foundation of a profitable operation. One of the most persistent challenges producers face is maintaining the correct particle size as material moves through the crushing circuit. Without real-time visibility, size variation can quickly lead to inefficiencies, downtime , and inconsistent end product. At KastRock, we focus on solutions that give producers better control over their process. Technologies like Metso RockSense 2D™ provide the real-time data needed to keep crushing operations running efficiently and predictably. What Is Metso RockSense 2D™? Metso RockSense 2D™ is an online particle size analysis system designed specifically for crushing applications. Using advanced 2D image analysis, it continuously measures the size distribution of material on a conveyor belt while production is running. Unlike traditional sampling methods that offer delayed or incomplete insights, RockSense 2D™ delivers instant, accurate feedback, allowing operators to make proactive adjustments and maintain consistent output. How the System Works RockSense 2D™ uses high-resolution cameras mounted above the conveyor to capture images of material as it moves through the process. Those images are analyzed in real time to determine particle size distribution and identify changes immediately. This continuous monitoring makes it easy to: • Track crusher discharge performance • Detect changes in material size early • Maintain target gradation throughout production The result is tighter process control without interrupting operations. Benefits of RockSense 2D™ for Aggregate Producers Real-Time Process Visibility • Continuously measures particle size on active conveyors • Instantly detects variations in material size • Designed for the demands of crushing environments Optimized Crushing Performance • Identifies process issues before they impact production • Supports faster, data-driven crusher adjustments • Helps improve uptime and overall plant efficiency Improved Product Consistency • Maintains uniform gradation across output material • Reduces variability that can affect downstream processes • Supports higher-quality end products With real-time particle size data, operators can respond quickly to changes in feed material and keep the crushing circuit running smoothly. Why Image-Based Particle Size Analysis Matters Traditional particle size sampling methods are often manual, time-consuming, and disruptive. They provide limited insight and can miss rapid changes in the crushing process. Image-based analysis with RockSense 2D™ offers a smarter alternative by delivering: • Continuous, non-intrusive measurement • Accurate and repeatable data • Zero interruption to material flow This allows producers to focus on optimization instead of reacting to problems after they occur. The KastRock Takeaway Real-time particle size monitoring changes how crushing operations perform. Metso RockSense 2D™ gives producers the visibility they need to improve efficiency, maintain consistent material quality, and reduce unplanned downtime. Contact us today to bring RockSense 2D™ to your operation!

KastRock, in partnership with Mellott , will host a Metso Product Line Customer Training event on April 14–15, 2026, in Lakeland, Florida. This two-day training is designed for customers looking to expand their knowledge of Metso crushing equipment through a combination of classroom instruction and hands-on demonstrations, providing practical insight that can be applied directly in the field. Two Days of Hands-On, Application-Focused Training The training will cover multiple Metso product lines, giving attendees exposure to a wide range of crushing solutions. Day One – April 14 • C-Jaw Crushers • Cone Crushers Day Two – April 15 • LT/ST Mobile Crushers • MC Product Line Both days will include hands-on demonstrations, allowing participants to see equipment operation up close, ask questions, and better understand best practices for operation and maintenance. Built Around Real-World Operation and Support KastRock’s customer training events are structured to support: • operators • maintenance personnel • supervisors and managers By blending technical instruction with hands-on experience, the training helps attendees improve equipment understanding, promote safe operation, and maximize performance at their sites. Event Details & Registration: Dates: April 14–15, 2026 Location: Lake Crago Recreational Center – Banquet Room 525 Lake Crago Dr. Lakeland, FL 33805 Cost: $550 per person Receive a 10% discount if registered and paid by March 31, 2026 Registration includes training materials, light breakfast, BBQ lunch, giveaways, and raffles. To register, scan the QR code on the event graphic or call 863-937-8859 for additional information.

Rock crushers are the backbone of every aggregate operation, turning raw stone into the materials needed for construction, roadwork, and infrastructure projects across the Southeast. But even the most dependable machines face extreme stress as abrasive stone, heavy loads, and continuous operation all contribute to wear over time. At KastRock, we help producers get the most from their crushing equipment through proper maintenance practices, quality wear parts, and smart operating strategies. Understanding why crusher components wear prematurely, and how to prevent it, can save your operation time, money, and unnecessary downtime. Understanding the Types of Rock Crushers Different crushing stages require different types of machines, each designed to break down material in a specific way. Knowing how each crusher functions helps operators maintain them correctly and choose the right wear components for the job. Primary Jaw Crushers Primary jaw crushers handle the first stage of material reduction. These machines process large, coarse stone using powerful, opposing jaw plates. One plate is stationary and the other moves in a compressive, oscillating motion. Jaw crushers are ideal for mine sites and quarry applications where massive feed sizes must be reduced to manageable dimensions before entering secondary processing. Secondary Impact Crushers Secondary impactors take material from the primary stage and further reduce it using high-speed rotating hammers. These machines excel at producing: • More cubical, uniform product • Cleaner aggregate shapes • Faster reduction of softer stones such as limestone or sandstone Impact crushers are a top choice for asphalt production, gravel manufacturing, and applications where shape and consistency matter. Tertiary Cone Crushers Cone crushers provide the final stage of material refinement. Inside the chamber, a spinning cone and hardened steel liners compress the material at high pressure, producing: • Precise sizing • Excellent shape • Minimal flat or elongated pieces These machines are essential for high-quality aggregates and applications requiring tight gradation control. Why Rock Crusher Wear Parts Fail Prematurely Every crusher type has wear components (liners, jaws, hammers, mantles, concaves, bearings, belts, and seals) that break down over time. Premature wear typically results from: • Highly abrasive feed material • Overloading the crusher • Incorrect feed distribution • Insufficient lubrication • Ignoring early signs of wear • Using low-quality aftermarket parts Without routine maintenance, small issues escalate quickly, leading to costly repairs or extended downtime. How to Minimize Wear and Extend Crusher Life Proper maintenance is the most effective way to extend the life of your crushing equipment. Here are KastRock’s top recommendations: 1. Perform Regular Inspections Routine checks help you catch early signs of wear before failure occurs. Inspect: • Bearings and seals • Liners and wear plates • Belts, drives, and tension systems • Feed chutes and discharge points Detecting issues early prevents larger, more expensive problems later on. 2. Choose Premium Wear Parts The quality of your wear components directly affects performance. High-grade alloys and OEM-spec materials last significantly longer and resist abrasion more effectively than cheaper alternatives. Investing in better parts can drastically reduce long-term maintenance costs. 3. Improve Lubrication Practices Using lubricants formulated for heavy-duty crushing equipment reduces friction, heat buildup, and component fatigue. Proper lubrication: • Enhances energy efficiency • Prevents metal-on-metal contact • Extends bearing and shaft life A consistent lubrication schedule is one of the simplest ways to prevent premature failures. 4. Maintain a Steady, Controlled Feed Uneven or overloaded feed can cause: • Shock loads • Excessive vibration • Rapid wear on internal components Feeding your crusher at a slow, steady, and consistent rate helps distribute material evenly across wear surfaces and protects the machine from unnecessary strain. 5. Keep Components Clean Dust and debris build up quickly in crushing environments. Keeping surfaces clean reduces friction, prevents contamination, and protects seals and moving parts. Even small amounts of debris can accelerate wear significantly. Protect Your Investment With Proper Crusher Maintenance Your rock crusher is a major investment and safeguarding it through proper care is essential for long-term success. By understanding the causes of premature wear and implementing proactive maintenance strategies, you can: • Reduce downtime • Improve operational efficiency • Extend component life • Maintain a safe working environment • Avoid unexpected repair costs At KastRock, we’re committed to helping customers keep their equipment running at peak performance. From high-quality wear parts to expert support, we provide the solutions you need to keep crushing efficiently.

At KastRock, our goal is to bring the industry’s best washing and classification solutions to your operation. That’s why we’re proud to offer Eagle Iron Works Double Fine Material Screw Washers , engineered to deliver superior washing, dewatering, and classification for fine materials. Why Choose Double Screw Fine Material Washers? Dual-Screw Efficiency for Demanding Operations Eagle Iron Works designs its fine material washers in single or double screw configurations to handle varying throughput needs. The double screw design is ideal when you require extra washing power and higher capacities without overworking a single shaft. Integrated Functions: Wash, Dewater & Classify These washers perform three essential tasks simultaneously: • Washing: The rotating screws, paired with inflow water, create particle-on-particle motion that removes coatings and fines. • Dewatering: As material is carried upward by the screws, drained water escapes through designed clearance paths, delivering drier product discharge. • Classification: Adjustable weirs allow you to control overflow velocity and separate finer particles when needed. These combined capabilities reduce the need for separate equipment, streamline your plant layout, and simplify logistics. Technical Highlights & Design Features Heavy-Duty Gear Reducer Eagle’s washers incorporate a robust gear reducer with helical gearing and triple-reduction design. This configuration enables operators to fine-tune the shaft speed from full capacity down to as low as 16%, matching performance to feed or mesh demands. Durable Shaft & Wear Components The conveyor shaft is built from heavy one-piece tubing with spiral segments welded in submerged arc fashion. Wear shoes cover the full face of the spiral, protecting against abrasion. Optional urethane wear shoes are available for certain applications. Flexibility via Adjustable Weirs To classify material precisely, Eagle washers feature three adjustable weirs. Whether you need strong retention or a hydraulic split, you can tailor overflow velocity to suit your feed. Configurations & Capacities Eagle offers a range of sizes in both single and double screw designs. Models are available in diameters and lengths to match your output needs, perfect for sand, fines, and delicate aggregates. How KastRock Delivers Value with EIW Washers Reliable Inventory & Quick Turnaround We stock common models and work closely with Eagle’s network to reduce lead times. Our goal is to get your screw washer installed and running with minimal downtime. Installation Support & Best Practices Our service team guides each installation, ensuring proper alignment, weir settings, and startup procedures so your equipment performs at peak capacity from day one. Ongoing Support & Lifecycle Management KastRock doesn’t stop at delivery. We assist with wear-part replacement, performance monitoring, and preventative maintenance to keep your washer in top condition. Contact us today to get information on the 54 X 34 and 66 X 35 Eagle Iron Works Double Fines Material Screw Washers that we have on-site and available for sale!

As the aggregate industry evolves, sustainability is no longer optional, it’s a competitive advantage. Across the sector, operators are shifting toward electric and hybrid equipment to lower emissions, reduce fuel costs, and build a reputation as environmentally responsible. At KastRock, we’re excited to bring you a used Eagle 1400-OC Electric Portable Plant , a machine that aligns productivity with sustainability goals. Why Sustainable Crushing Matters Today Modern regulations, community concerns, and corporate ESG (Environmental, Social, Governance) goals are pushing aggregate producers to rethink how they power their plants. Some of the drivers include: • Reduced carbon footprint: Electric motors, when powered by clean grids or renewable energy, emit far less CO₂ than diesel systems. • Lower operational costs: Electricity often costs less per horsepower-hour than diesel, and maintenance on electric drives is simpler (fewer fluids, fewer moving hydraulic parts). • Noise & emissions control: Electric plants tend to run quieter and produce fewer exhaust emissions — an advantage in urban or regulated areas. • Future-proofing your investment: As grid infrastructure and clean energy grow, electric plant options will only become more attractive. These themes echo what leading equipment companies are promoting today. For example, our partner Mellott recently published an article on how electric and hybrid crushing and screening machines help producers reduce fuel consumption and greenhouse gas emissions while maintaining performance. How the Eagle 1400-OC Electric Contributes to a Greener Footprint The Eagle 1400-OC (Open Circuit) has features and design elements that support a more sustainable operation without compromising on throughput or robustness. Some of the advantages include: Fully Electric or Hybrid Drive Options The 1400-OC platform can operate in an electric-powered mode (or hybrid) so you can reduce reliance on diesel engines. This directly translates to lower fuel burn and cleaner onsite operations. Efficient Material Handling & Pre-Screening With a 2-step grizzly deck before the impactor, the 1400-OC removes fines early, reducing over-processing and wasted energy. This makes the crushing process more efficient and less wasteful. Rapid Setup & Modularity Its hydraulic legs, well-designed layout, and prewired electrical panels help shrink installation time, which means less idle time and associated energy waste. Durable Design & Component Life The plant’s heavy rotor, replaceable wear components , and modular build help extend service intervals. Less frequent part replacement means fewer manufactured parts in circulation, which supports sustainability through reduced waste. These traits make the Eagle 1400-OC a smart option for operators looking to produce more responsibly, without sacrificing crushing power. Ready for a Smarter, Cleaner Plant? If you want to step into the future of crushing and combine performance, efficiency, and environmental responsibility this Eagle 1400-OC Electric Portable Plant is right for you. Contact us today !

At KastRock, we know that in the aggregate industry, downtime is costly. Every minute a crusher sits idle means lost productivity, delayed schedules, and increased expenses. One of the best ways to minimize downtime is by investing in high-quality crusher parts that are built to last. While lower-cost alternatives may seem appealing in the short term, they often lead to faster wear, more frequent replacements, and greater overall costs. Here’s why quality parts are the smarter investment for your operation. 1. Longer Lifespan and Better Performance Premium wear parts such as jaw plates, liners, and blow bars, are engineered from durable alloys that withstand extreme wear and tear. This means fewer part replacements and consistent crusher performance over time. 2. Reduced Maintenance Costs Cheap parts often require more frequent maintenance and unexpected repairs. By choosing high-quality replacements from a trusted supplier, you’ll save money on labor, reduce the need for emergency service calls, and keep your equipment running smoothly. 3. Improved Productivity and Uptime The reliability of your crusher parts directly impacts your operation’s efficiency. Investing in premium parts reduces the risk of sudden breakdowns, keeping your team focused on production instead of troubleshooting equipment failures. 4. Safety and Peace of Mind Worn-out or poorly manufactured parts can compromise not only your crusher’s performance but also operator safety. With quality components, you minimize equipment stress and create a safer, more predictable working environment. 5. Long-Term Cost Savings While high-quality parts may cost more upfront, they pay off in the long run by lasting longer, reducing downtime, and boosting overall productivity. Think of it as an investment in the success and sustainability of your operation. Partner with KastRock for Reliable Crusher Parts At KastRock, we’re committed to helping aggregate producers maximize uptime and reduce long-term costs with durable equipment and quality parts. Our team is here to provide the expertise and support you need to keep your operation running at its best. Learn more about our crusher parts and equipment solutions today!

Looking for a powerful, reliable, and cost-efficient portable impactor plant? The Eagle UltraMax® 1400-45 OC Electric Portable Plant is built to handle big jobs with unmatched durability—and we’ve got one in stock right now at KastRock Mellott in Lakeland, Florida. Why the UltraMax 1400-45 OC Stands Out This open-circuit portable plant is designed to simplify your crushing operation without sacrificing performance. Its heavy-duty build and streamlined setup make it one of the most efficient crushers in the industry. Key Features: UltraMax UM-45 Impactor with Eagle’s industry-leading lifetime rotor warranty Hydraulic lift and leveling system for fast, hassle-free setup and teardown Side-discharge conveyor with optional in-line magnet to keep your material clean Two-step, 5′ grizzly deck with bypass chute for fines removal and blending options Variable Frequency Drive (VFD) for precision feeder speed control Wireless remote control for feeder and system shutdown Specs at a Glance: Operating Length: 50′ (15.2 m) Travel Dimensions: 44′ 6″ L x 11′ 11″ W x 13′ 5″ H Gross Weight: 123,000 lbs (55,800 kg) Why Buy from KastRock Mellott? ✅ In Stock Today – No long lead times. ✅ Free Startup Assistance – Our experts will get you up and running at no cost. ✅ No Tariffs – Buy with confidence and save. ✅ Local Support – Backed by Mellott’s unmatched service network in Florida and beyond. If you’re ready to add serious production power to your operation, the Eagle UltraMax 1400-45 OC at KastRock Mellott Lakeland is the machine for the job. 📞 Contact our Lakeland team today at 863-937-8859 or contact us here to schedule a walk-around or secure this unit before it’s gone!

Share On: