By 7016535987

•

November 20, 2025

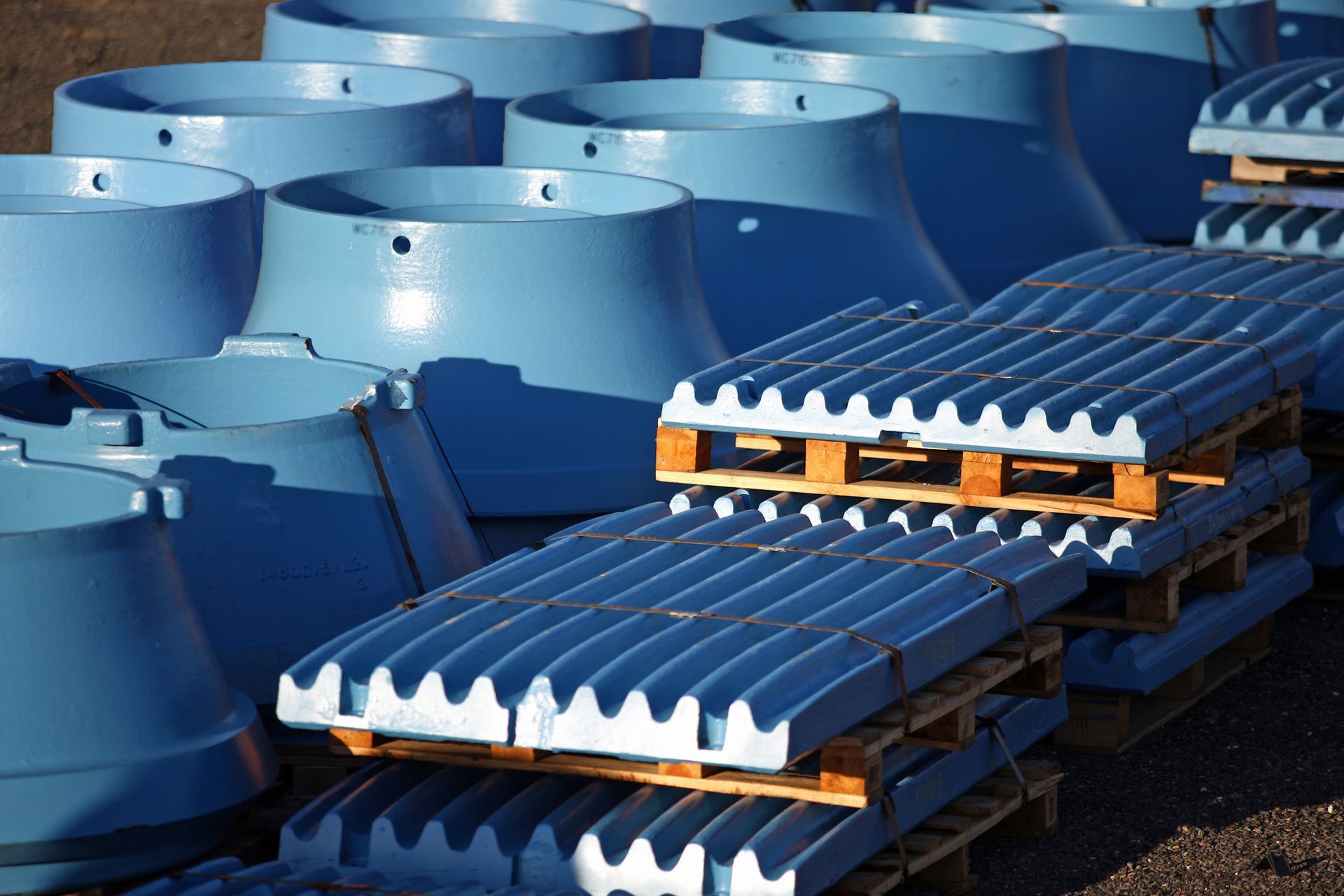

Rock crushers are the backbone of every aggregate operation, turning raw stone into the materials needed for construction, roadwork, and infrastructure projects across the Southeast. But even the most dependable machines face extreme stress as abrasive stone, heavy loads, and continuous operation all contribute to wear over time. At KastRock, we help producers get the most from their crushing equipment through proper maintenance practices, quality wear parts, and smart operating strategies. Understanding why crusher components wear prematurely, and how to prevent it, can save your operation time, money, and unnecessary downtime. Understanding the Types of Rock Crushers Different crushing stages require different types of machines, each designed to break down material in a specific way. Knowing how each crusher functions helps operators maintain them correctly and choose the right wear components for the job. Primary Jaw Crushers Primary jaw crushers handle the first stage of material reduction. These machines process large, coarse stone using powerful, opposing jaw plates. One plate is stationary and the other moves in a compressive, oscillating motion. Jaw crushers are ideal for mine sites and quarry applications where massive feed sizes must be reduced to manageable dimensions before entering secondary processing. Secondary Impact Crushers Secondary impactors take material from the primary stage and further reduce it using high-speed rotating hammers. These machines excel at producing: • More cubical, uniform product • Cleaner aggregate shapes • Faster reduction of softer stones such as limestone or sandstone Impact crushers are a top choice for asphalt production, gravel manufacturing, and applications where shape and consistency matter. Tertiary Cone Crushers Cone crushers provide the final stage of material refinement. Inside the chamber, a spinning cone and hardened steel liners compress the material at high pressure, producing: • Precise sizing • Excellent shape • Minimal flat or elongated pieces These machines are essential for high-quality aggregates and applications requiring tight gradation control. Why Rock Crusher Wear Parts Fail Prematurely Every crusher type has wear components (liners, jaws, hammers, mantles, concaves, bearings, belts, and seals) that break down over time. Premature wear typically results from: • Highly abrasive feed material • Overloading the crusher • Incorrect feed distribution • Insufficient lubrication • Ignoring early signs of wear • Using low-quality aftermarket parts Without routine maintenance, small issues escalate quickly, leading to costly repairs or extended downtime. How to Minimize Wear and Extend Crusher Life Proper maintenance is the most effective way to extend the life of your crushing equipment. Here are KastRock’s top recommendations: 1. Perform Regular Inspections Routine checks help you catch early signs of wear before failure occurs. Inspect: • Bearings and seals • Liners and wear plates • Belts, drives, and tension systems • Feed chutes and discharge points Detecting issues early prevents larger, more expensive problems later on. 2. Choose Premium Wear Parts The quality of your wear components directly affects performance. High-grade alloys and OEM-spec materials last significantly longer and resist abrasion more effectively than cheaper alternatives. Investing in better parts can drastically reduce long-term maintenance costs. 3. Improve Lubrication Practices Using lubricants formulated for heavy-duty crushing equipment reduces friction, heat buildup, and component fatigue. Proper lubrication: • Enhances energy efficiency • Prevents metal-on-metal contact • Extends bearing and shaft life A consistent lubrication schedule is one of the simplest ways to prevent premature failures. 4. Maintain a Steady, Controlled Feed Uneven or overloaded feed can cause: • Shock loads • Excessive vibration • Rapid wear on internal components Feeding your crusher at a slow, steady, and consistent rate helps distribute material evenly across wear surfaces and protects the machine from unnecessary strain. 5. Keep Components Clean Dust and debris build up quickly in crushing environments. Keeping surfaces clean reduces friction, prevents contamination, and protects seals and moving parts. Even small amounts of debris can accelerate wear significantly. Protect Your Investment With Proper Crusher Maintenance Your rock crusher is a major investment and safeguarding it through proper care is essential for long-term success. By understanding the causes of premature wear and implementing proactive maintenance strategies, you can: • Reduce downtime • Improve operational efficiency • Extend component life • Maintain a safe working environment • Avoid unexpected repair costs At KastRock, we’re committed to helping customers keep their equipment running at peak performance. From high-quality wear parts to expert support, we provide the solutions you need to keep crushing efficiently.

Share On: